July 2022

Time to Toss That PPE?

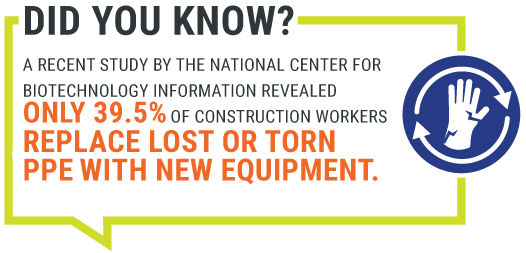

Every year, tons of defective, damaged, and used PPE get tossed - as it should! OSHA’s Personal Protective Equipment standard says you must not use ANY defective or damaged PPE. Yet, workers still get hurt from using inadequate protection.

Your workers should always follow your company’s policy for cleaning, decontaminating, and maintaining PPE. Provide employees this downloadable PPE inspection checklist to help workers ensure their PPE is in good working order to keep them safe on the job.

Check It Out

Before using any PPE, your workers should regularly hold it up to the light and check for damages. Below you’ll find a list of what to look for with various types of PPE.

Hi-Vis Apparel

After about six months of regular use, any hi-vis apparel should be inspected for wear and tear, especially as it may no longer meet ANSI visibility standards.

Look for:

- color fading

- damage or wear on the reflective strips

- excessive dirt that won’t come off

- rips and tears

Gloves

Using safety gloves that are past their prime can lead to cuts or loss of grip, which can cause injuries.

Look for:

- worn spots

- fabric snags

- holes or tears

- coating that is peeling

- significant soiling

Safety Glasses & Goggles

It’s critical to protect your employees’ eyes from flying debris, dust and chemical splashes. Safety glasses and goggles that are damaged compromise your employees’ eyesight.

Look for:

- color fading

- damage or wear on the reflective strips

- excessive dirt that won’t come off

- rips and tears